PROCESSING

Internal design, engineering, and industrialisation, management of external suppliers for the production of any type of product, treatment or processing, "just in time" delivery, worldwide shipping… these are just some of the services we offer to our clients.

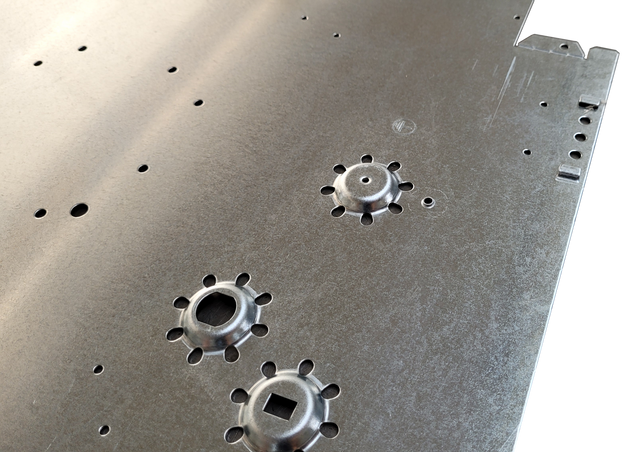

Punching machines and laser cutting are crucial elements in sheet metal processing.

Thanks to our punching machines, we can deform and cut sheet metal to achieve exactly what the client desires, in very short times and at low costs.

Our

Trumpf-Trumatic L3030 Laser Cutting system allows for extremely flexible processing and can cut thicknesses up to five times greater than the punching machine, ensuring an excellent cut finish with smooth, burr-free pieces.

Bending

The process following cutting is bending.

Bending sheet metal is a mechanical operation where a specific object is deformed by applying forces using special machinery called bending machines.

Our

bending machines can perform any bend requested by the client, using processes and technologies that ensure the highest quality.

Panel bending

An alternative technology to the bending machine is the panel bender.

Our Salvagnini P2 panel bender, with its automatic bending cycles, manipulation, flexibility, and universal bending tools, can bend most panels available on the market, meeting every client’s request.

Key advantages include speed of bending, the ability to perform operations such as riveting or inserting fasteners during the machine’s work cycle, and guaranteed excellent repeatability of bends.

Welding and spot welding

In our welding and spot welding department, we perform manual MIG, MAG, TIG, Laser welding, and electric spot welding.

Riveting, inserting fasteners, and inserts

In addition to welding, we carry out interventions to complete the product and enhance its usability:

Riveting: Where welding is not possible or necessary, riveting is the most common method to ensure the joining of two sheets in a short time.

Inserting fasteners: Inserting fasteners can be done under pressure using our Haeger machine, or via high-voltage electric discharge that welds the threaded pin to the metal surface.

Inserting inserts: Inserting inserts is equally important as it allows, using an insert machine, to achieve threads even in thin sheets.

Surface treatments and assembly

We work with leading companies in the industry to provide surface treatments such as painting, galvanising, screen printing, cathodic dip coating, and many others.

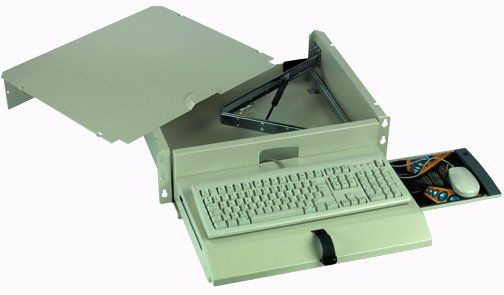

The final stages of processing are assembly and packaging.

Gallery of finished products